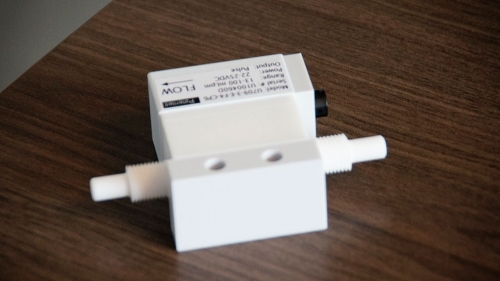

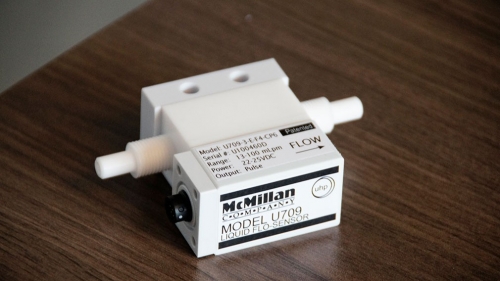

McMillan Model U709 UHP Liquid FLO-MONITORS will precisely measure flow rates of virtually any photoresist chemical, whether a short burst of flow or a continuous flow. Dispenses as short as 500 milliseconds and volumes as low as 0.1 grams can be detected repeatably.

Repeatable results are achieved by using a patented microturbine flow sensor design. This design, unlike traditional paddlewheel designs, provides accurate flow measurement with no particle generation or elemental contamination. PTFE, perfluoroelastomers, and sapphire wetted parts ensure compatibility with chemicals commonly found in microelectronics manufacturing processes, including deionized water, CMP slurries, acids, solvents, and photoresist.

These FLO-MONITORS integrate the sensing element with advanced electronics to provide output signals proportional to flow rate. Each unit is individually calibrated before shipment, and a certificate of calibration accompanies all FLO-MONITORS. The reliable technology used reassures process engineers of consistent repeatable results.

ITY Pulse output models have an accuracy specification of ±3.0% full scale or better (including linearity) for stable viscosities.

CALIBRATION

All units are calibrated at the factory using deionized water and a calibration certificate is supplied with each unit. For fluids with viscosities different to water please contact the factory for further information.

DISPLAYS

McMillan has a comprehensive range of remote displays for use with UHP FLO-MONITORS. Please request further information from the factory.

ELECTRICAL CONNECTIONS

All units have an integrated 7-pin connector. Several mating cable options are available.

FLOW RANGES

Continuous flow ranges from 7-50 mLpm up to 100-1,000 mLpm are available. Consult the factory for custom requirements.

FLUID CONNECTIONS

All units have male Flaretek compatible connectors. Non-standard connection types may be available upon request. POWER Unit may be specified to operate with either 12 VDC or 24 VDC power.

SIGNAL OUTPUTS

The Model U709 features a pulse output, typically 0-200 Hz up to 0-800 Hz (consult the units calibration certificate for the exact frequency output).

WETTED MATERIALS

All units have only PTFE, perfluoroelastomers, and sapphire as wetted parts.

Specifications

- Accuracy (including linearity, best fit straight line):

- ±3.0% Full Scale

- Repeatability:

- up to ±0.2% Full Scale (based on average of multiple readings)

- Pressure Rating:

- 80 psig (5.4 bar) working

100 psig (6.8 bar) overpressure - Temperature Rating (Fluid):

- 5 to 45ºC

- Temperature Rating (Environment):

- Operating: 5 to 45ºC

Storage: 0 to 70ºC - Wetted Materials:

- PTFE

Sapphire - Exterior Surfaces:

- PTFE

Polypropylene

Polyester

Viton

Epoxy - O-Ring Material:

- Perfluoroelastomer (check with factory for current compound)

- Recommended Filtration:

- 20 microns or less

- Compatible Liquids:

- Minimum amount of entrained air

Optimum performance with stable liquid viscosities (<80 cS) - Warm-Up Time:

- None

- Zero Drift:

- None

- Calibration Interval:

- Calibration should typically be verified once every 12 months

- Power Requirements:

- 12 VDC Units: 12-15 VDC, 50 mA typical

24 VDC Units: 22-25 VDC, 50 mA typical - Electrical Connections:

- 7-pin connector

Nylon housing with used with CPx cables - Typical Response Time:

- Typically <300 milliseconds for 97% of final value

- Reliability:

- 100,000 hours MTBF (testing ongoing)

- Approvals/Certifications:

- CE Approved

89/336/EEC(EN 55011 & EN 50082-1)

73/23/EEC Low Voltage Directive - Ratings:

- IP64 (NEMA 4X)

- Pulse Output:

- Square-wave

Collector output

Pulls up to V+

Frequency output at max flow varies from 300-500 Hz depending on orifice and media

|

||||

|