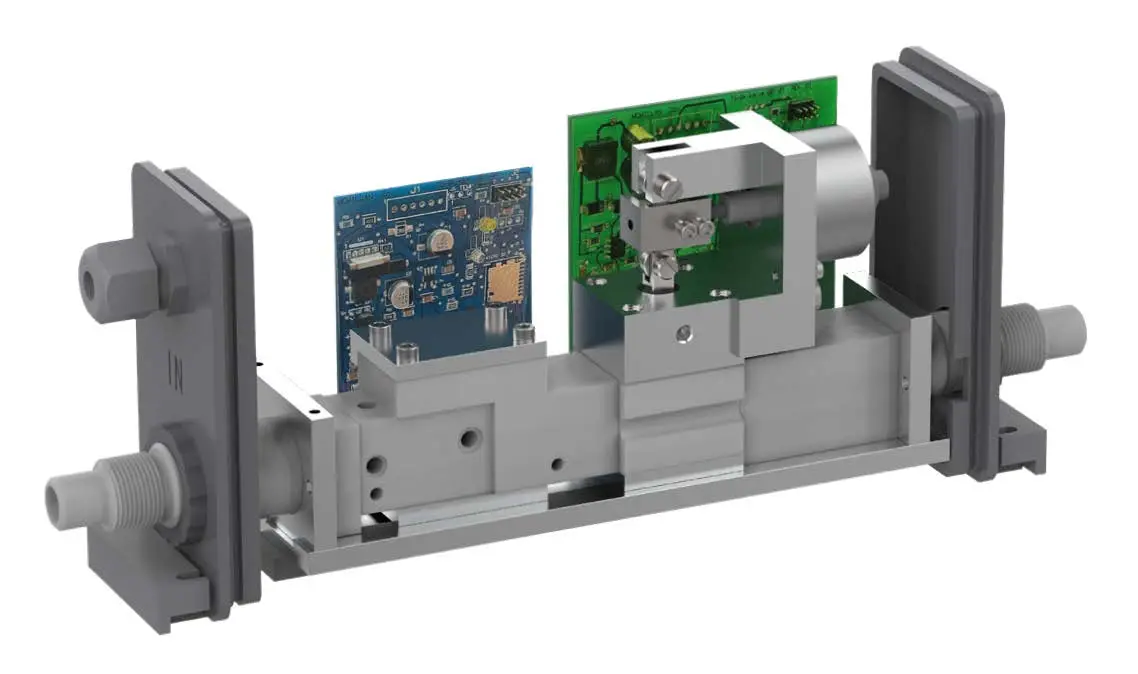

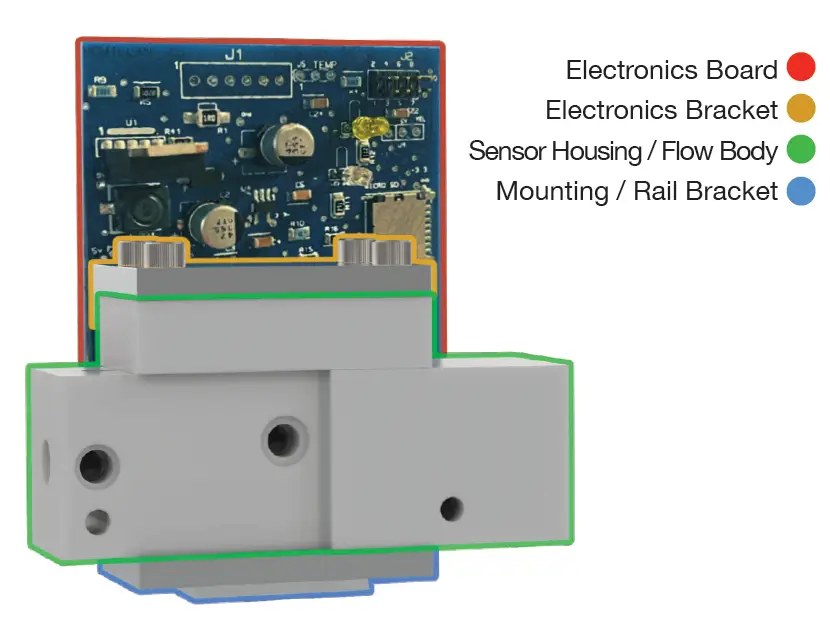

The 6010-01 features an Integrated Package where all electronics and interfaces are contained in a single case. IRIDIUM is a platform for configurable flow control. Its modular design allows for a single device to adapt to a variety of flow conditions and applications. Standard configurations are available for liquid flow rate regulation.

IRIDIUM is a platform for configurable flow control. Its modular design allows for a single device to adapt to a variety of flow conditions and applications. The primary unit features the exterior case, touchscreen, connectors, and rails for flow path blocks.

There are two packages for the IRIDIUM series flow controller; an Integrated Package (6010-01) where all electronics and interfaces are contained in a single case, and a Remote Display Package with two cases, where the touchscreen and wiring ports are mounted remotely from the flow path blocks.

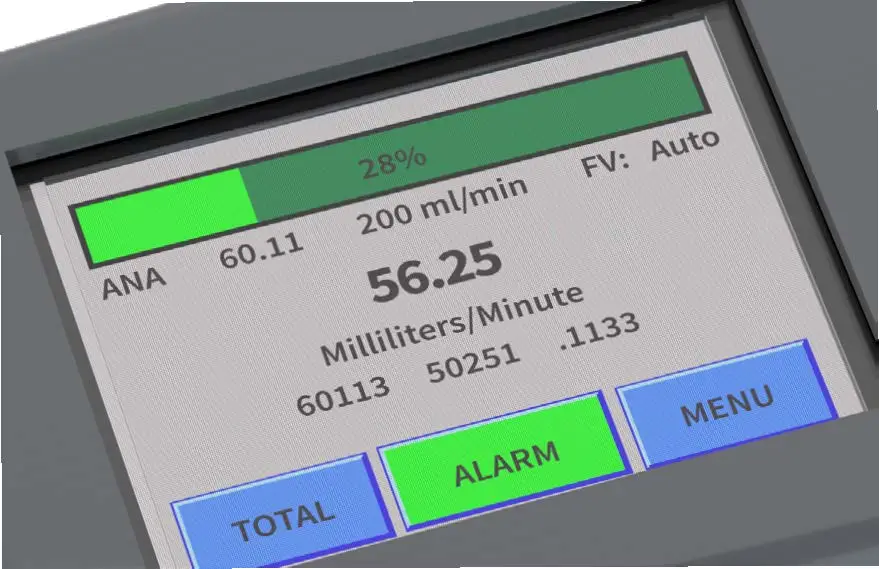

A 3.2″ [ 81 mm ] LCD color touchscreen is included in both packages. This touchscreen allows for monitoring of flow rate, inputting data, and configuring the unit on site. In addition, RS485 serial and USB communications are standard for remote interfacing.

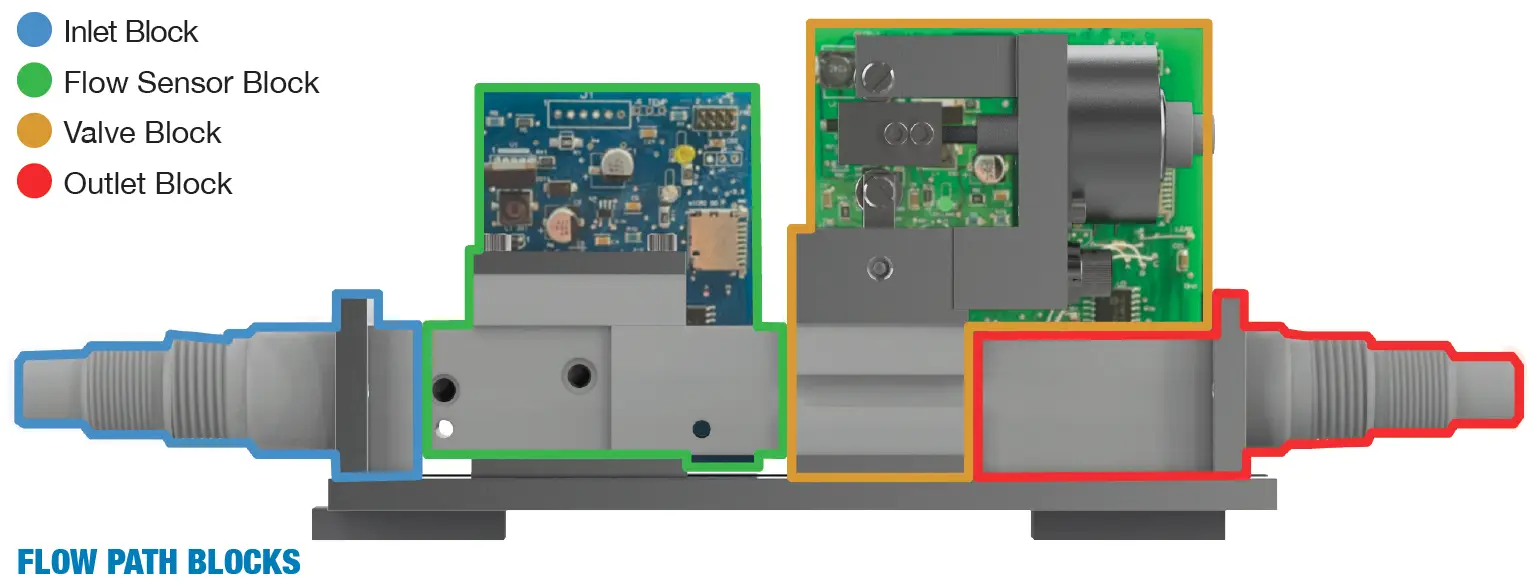

The IRIDIUM flow unit accepts four flow path blocks:

1) inlet block; 2) flow sensor block; 3) valve block; and 4) outlet block (See flow path blocks diagram below.) In addition, it features two expansion slots for enhanced I/O functionality.

Factory-built configurations are available in both the Integrated and Remote Display Packages. To simplify configuration, these combine compatible flow path blocks to allow the ordering of one part number for a complete solution.

The IRIDIUM platform requires 24 VDC power. Various power adapters are also available for use as needed. The unit cannot be powered through the USB port.

All units can be completely controlled through the on-board touchscreen. In addition, full remote control is available through the RS485 serial connection, and limited control is available through the USB port. An optional expansion module also adds analog I/O functionality (EAA module).

The IRIDIUM platform can easily be customized through downloadable firmware updates via the micro-USB port. The factory can provide custom software packages with unique configurations to match specific applications or process conditions.

A 15-pin D-SUB connector provides all power and signal connections to the IRIDIUM, with the exception of the USB port. Various adapters and hubs are available to adapt the connector to wiring terminals or other interfaces.

All IRIDIUM packages incorporate a 3.2” [ 81 mm ] color touchscreen that provides readouts of current flow rate, total flow, and system status. The touchscreen can also be used to configure the IRIDIUM settings, adjust set-points and alarms, and troubleshoot errors. The touchscreen can become a digital keypad for simple numeric value entry when needed.

Enables the IRIDIUM to receive and transmit analog signals such as 4-20 mA, 0-20 mA, 0-10 VDC, or 0-5 VDC. All signals are fully isolated.

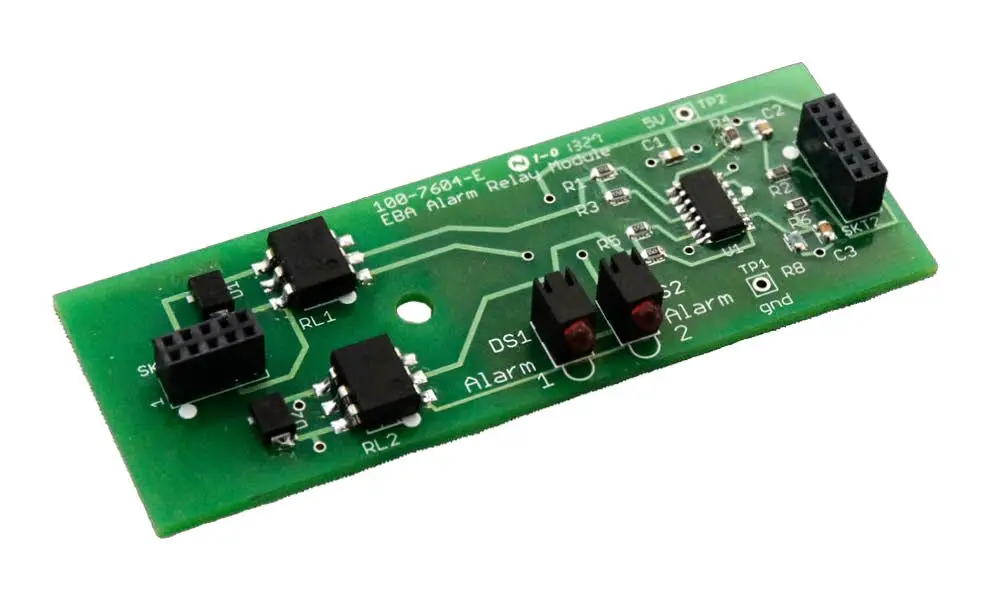

Enables the alarms that are built-in to the IRIDIUM to be transmitted externally via solid-state relay contacts.

Currently, McMillan offers one type of inlet/outlet block, one flow sensor block type, and one valve block type.

To facilitate connections to the fluid systems, the F601 inlet and outlet male flare blocks are machined from PTFE and are available in 1/4”, 3/8” and 1/2” sizes (examples in Figure 1a). Male flare connections accept flared PFA tubing and require flare nuts to secure (available as accessories).

Male flare to NPT adapters are available to adapt 1/4” male flare connections to 1/8” FNPT (P/N 861-370) and 3/8” male flare connections to 1/4” FNPT (P/N 861-380). These adapters are illustrated in Figure 1b.

Two F601 blocks are required for each working IRIDIUM configuration. The inlet and outlet can be different sizes as required by the application.

McMillan’s microturbine wheel technology (explained more on the microturbine technology page) utilizes the Pelton turbine wheel concept. This design allows for the use of a miniature turbine wheel supported by a very small sapphire shaft. The shaft is held in position by two maintenance-free bearings. Due to the light weight of both the wheel and the shaft, the microturbine wheel is virtually suspended in the flow path.

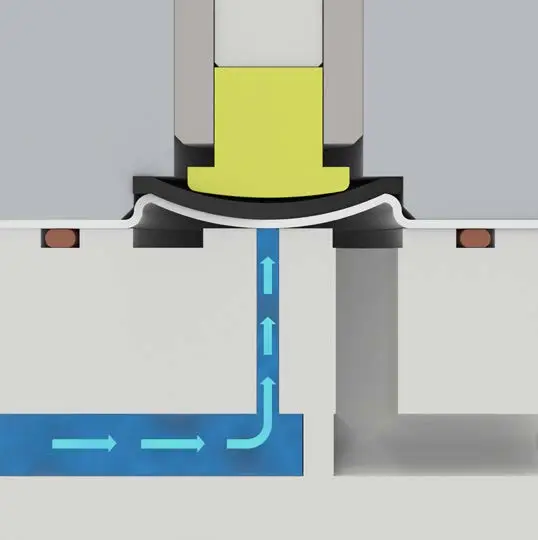

To provide responsive control of flow rate, the B601 applies pressure to a large diaphragm that proportionally opens and closes the fluid pathway. This diaphragm is actuated by a precision engineered cam driven perpendicular to the diaphragm with the use of a stepper motor. As the stepper cam extends, it applies more pressure to the diaphragm.

In addition to inputs provided by the flow sensor block, the B601 is also able to predictively estimate cam location based on set-point changes. This reduces response time to achieve large changes in flow rate based on large changes in the set-point.

The B601 is designed exclusively for proportional control. It is not designed for a positive shutoff. Contact the factory or an authorized representative for details on using the IRIDIUM to control an external shutoff valve for dispense applications.

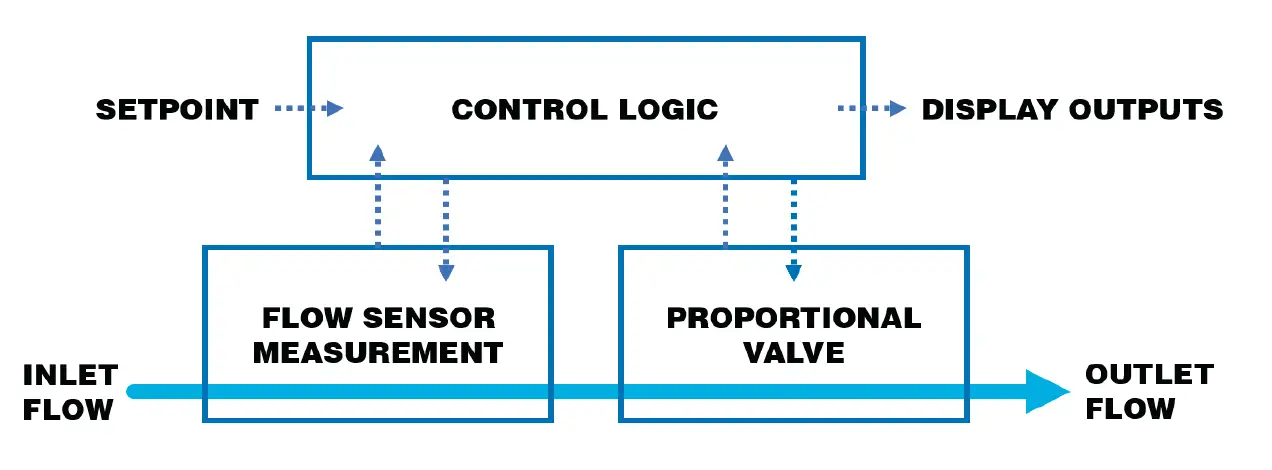

Flow controllers use an integrated flow rate sensor and control valve to regulate flow rate, regardless of inlet pressure fluctuations. A flow control set-point is provided by the user via the touchscreen, or remotely via an electronic signal. The controller then adjusts the integrated valve as needed to maintain the desired flow rate.

MODULAR DESIGN

ACTIVE FLOW AND ALARM MONITORING

EASY MENU OPTION NAVIGATION

ON-SITE VALVE SET-POINT ADJUSTMENTS

ON-SITE FLOW CALIBRATION OPTIMIZATION

ANALOG I/O MODULE (EAA)

ALARM OUTPUT MODULE (EBA)

FLOW PATH BLOCKS

INLET/OUTLET BLOCKS

FLARE TO NPT ADAPTERS

FLOW BODY SECTION

VALVE OPEN

VALVE CLOSED

FLOW CONTROLLER LOGIC

Operating Temperature: 32 to 122 °F [ 0 to 50 °C ]

Storage Temperature: 32 to 158 °F [ 0 to 70 °C ]

Relative Humidity: 20 to 85%

USB 2.0 Micro-A

RS485

VDC Input

0-10 VDC or 0-5 VDC, user selectable

200 Kohm or higher typical input resistance

Isolated from power

VDC Output

0-10 VDC or 0-5 VDC, user selectable

5 Kohm or higher acceptable load

Isolated from power

mA Input

0-20 mA or 4-20 mA, user selectable

Isolated from power

mA Output

(0-20 mA or 4-20 mA, user selectable

Passive, 500 ohm or lower loop resistance

Isolated from power

2 relays

User configurable menu selections

Rating: maximum 0.4 A, 30 VDC

< 10 seconds typical

Recommended Voltage: 24 VDC

(16-25 VDC, user selectable)

2.5 watts typical power consumption

Reverse polarity and over-voltage protected

15-pin Male D-Sub

Micro-USB

3.2” [ 81 mm ] TFT LCD color display

Resistive touchscreen panel

CE Approved; 89 / 336 / EEC (EN 55011 & EN 50082-1)

73 / 23 / EEC Low Voltage Directive

UKCA

IP63

1 year limited

MAXIMUM PRESSURE RATING

80 psig [ 5.4 barg ] burst pressure

60 psig [ 4.2 barg ] max operating pressure

TEMPERATURE RATING (FLUID)

41 to 104 °F [ 5 to 40 °C ]

Higher temperature modules may be available

ACCURACY (INCLUDING LINEARITY, BEST FIT STRAIGHT LINE)

± 1.0% typical from factory, full scale

± 0.5% typical with user calibration, full scale

REPEATABILITY

± 0.5% or better typical

± 0.2% best conditions

WETTED MATERIALS

PTFE

Sapphire

SEAL MATERIALS

FKM standard

FFKM option available [EKZ]

COMPATIBLE FLUIDS

Most low viscosity fluids (< 15 cS)

Minimum of entrained air - at low flow ranges

ZERO DRIFT

None

MAXIMUM PRESSURE RATING

80 psig [ 5.4 barg ] burst pressure

60 psig [ 4.2 barg ] max operating pressure

TEMPERATURE RATING (FLUID)

41 to 104 °F [ 5 to 40 °C ]

Higher temperature modules may be available

VALVE TYPE

PTFE diaphragm, cam-driven

RESPONSE TIME

Adjustable, typically < 2 seconds to final value

WETTED MATERIALS

PTFE

FFKM

SEAL MATERIALS

FKM standard

FFKM option available [EKZ]

DIFFERENTIAL PRESSURE TYPICAL CONFIGURATION

20 psid [ 1.4 bar ] to reach 100% rated flow

Minimum 5 psid [ 0.3 bar ] to reach 50% rated flow

Not to exceed 50 psid [ 3.4 bar ]

Other differential pressure configurations available

861-300

6 ft [ 2m ] DB15 extension cable (M-F)

861-301

301 10 ft [ 3m ] DB15 extension cable (M-F)

861-310

Female DB15 connector block kit (for easy wiring)

861-304

6 ft [ 2m ] Micro USB cable kit

861-320

Tabletop tilt stand

861-360

Power supply kit, includes 6 ft [ 2m ] cable, power supply and block kit

861-370

HDPE & Viton 1/4” male flare to 1/8” FNPT (each)

861-380

HDPE & Viton 3/8” male flare to 1/4” FNPT (each)

We are experts in all things flow. As a company founded and run by engineers, we seek to understand your application and then build a product solution that will solve your most difficult challenges.

McMillan Flow sales agents are strategically located across the

globe. Find your nearest distributor or office.

McMillan Company

7075 Ranch Rd 2338

Georgetown, TX 78633

sales@mcmflow.com

Phone: (844) MCM-FLOW

Copyright © 2024 McMillan Flow Products. All Rights Reserved.

McMillan Flow Products is located in the U.S.A. and all products are manufactured in our Texas plant.

"*" indicates required fields